factory Outlets for Beer Forced Carbonation - High Purity Flow Restrictors uesd in high-flow C-Seal configuration gas systems / flow setting device for gas processes – HENGKO

factory Outlets for Beer Forced Carbonation - High Purity Flow Restrictors uesd in high-flow C-Seal configuration gas systems / flow setting device for gas processes – HENGKO Detail:

High Purity Flow Restrictors uesd in high-flow C-Seal configuration gas systems / flow setting device for gas processes

HENGKO delivers precision porous metal flow restrictors that provide a reliable and economical replacement for small control valves. A porous metal flow restrictor is a passageway with many small holes that creates a large number of random streams. Flow restrictors are suitable for use in gaseous as well as liquid environments. For liquid environments special flow restrictors are available. The flow restrictors are available in stainless steel, Inconel and Monel for an optimal protection against corrosion.

The flow restrictors are available in a wide range of porosity to ensure the perfect flow rate for the desired applications. A porous metal flow restrictor has a porous surface that is 500 times as large as that of similar passages without porous material. The advantage is that a laminar flow will be created with a minimal disturbance in speed, pressure and temperature as compared to an orifice.

Want more information or wouldl like to receive a quote?

Click the Online Service at the top right to contact our salespeople.

E-mail:

<img src="/uploads/HTB1QIYrHXXXXXXnXFXXq6xXFXXXI.jpg" alt="sintered 316L porous stainless steel metal filter plate used to delete the mist drop" width="750" ori-width="600" ori-height="600">

-- Sure, no problem.

Product detail pictures:

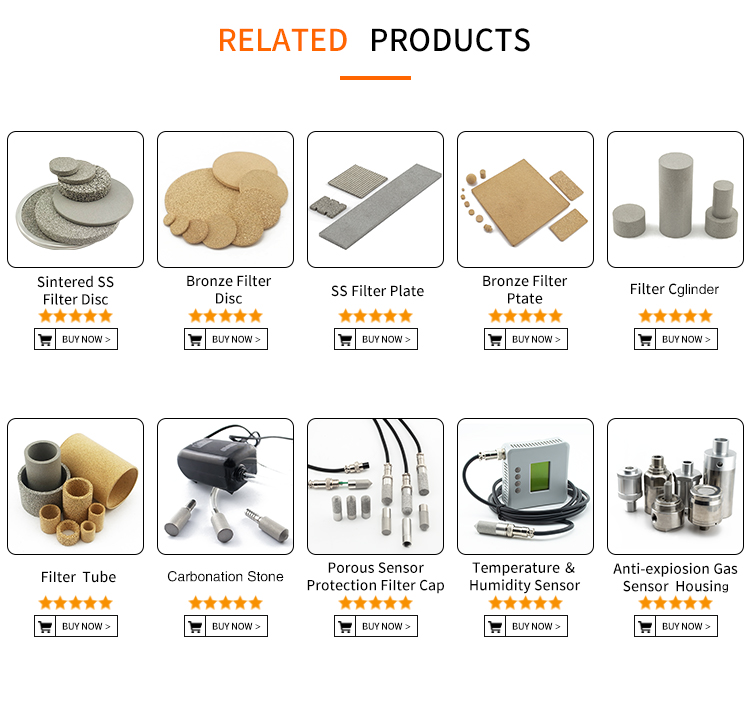

Related Product Guide:

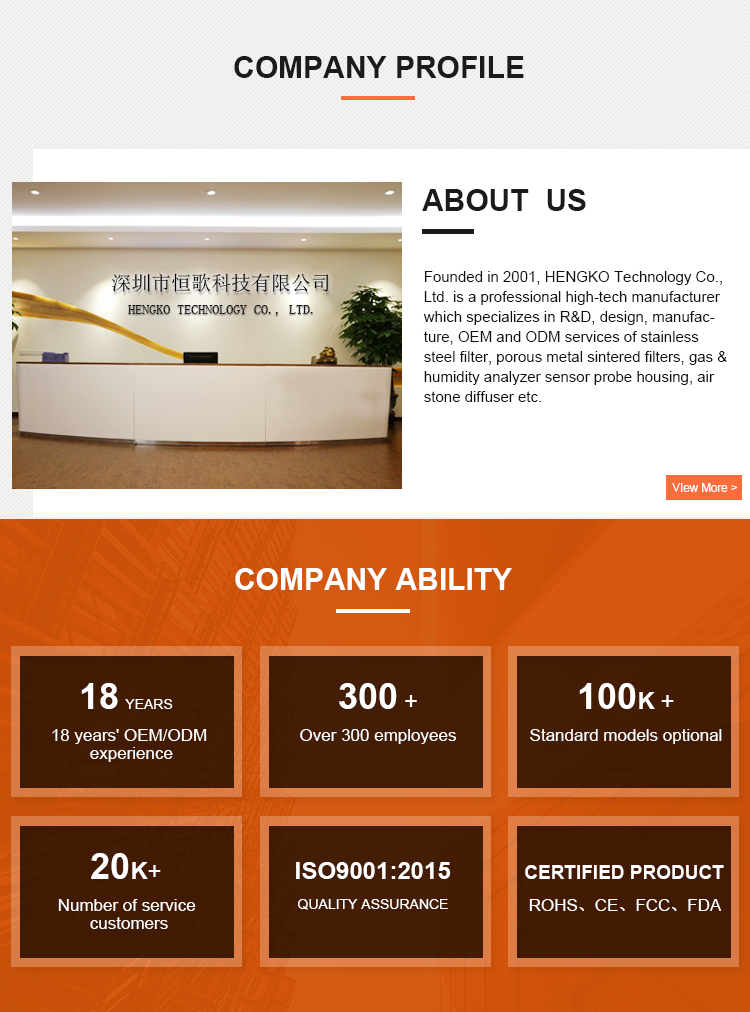

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for factory Outlets for Beer Forced Carbonation - High Purity Flow Restrictors uesd in high-flow C-Seal configuration gas systems / flow setting device for gas processes – HENGKO, The product will supply to all over the world, such as: Romania , New Delhi , Boston , Welcome to visit our company, factory and our showroom where displays various products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.