4-20mA Temperature and humidity sensor with PLC Realize Temperature control

Achieve Optimal Injection Molding Results with our Advanced Dehumidification System!

In injection molding operations, achieving low mold coolant temperatures is crucial for superior results. However, rapid cooling often leads to condensation issues, causing corrosion, quality defects, and compromised products.

Introducing our game-changing solution: PLC + Temperature and Humidity Transmitter. This cutting-edge dehumidification system efficiently dries the air surrounding the mold, effectively eliminating condensation-related problems.

Here's how it works:

- Energy-efficient rotary dehumidifiers remove moisture from the air, ensuring a dry environment.

- By maintaining dry air, our system prevents water vapor from condensing on the cooled mold surface, eliminating water marks and cracks.

- The temperature and humidity transmitter accurately detects ambient conditions, with a wide temperature range (-40°C to 125°C) and precise humidity detection (0% to 100% RH).

- It provides a reliable analog signal (4-20mA) for seamless integration into various temperature and humidity control systems.

Experience the Benefits:

- Exceptional Performance: Our system guarantees stable and efficient dehumidification, safeguarding molds and enhancing product quality.

- Corrosion Prevention: Bid farewell to mold problems caused by condensation-related corrosion, ensuring long-lasting mold durability.

- Enhanced Product Aesthetics: Say goodbye to unsightly water marks and cracks, as our system keeps products pristine and defect-free.

Don't let condensation hinder your injection molding success. Invest in our state-of-the-art dehumidification system today and unlock the full potential of your injection molding operations. Place your order now to experience game-changing results!

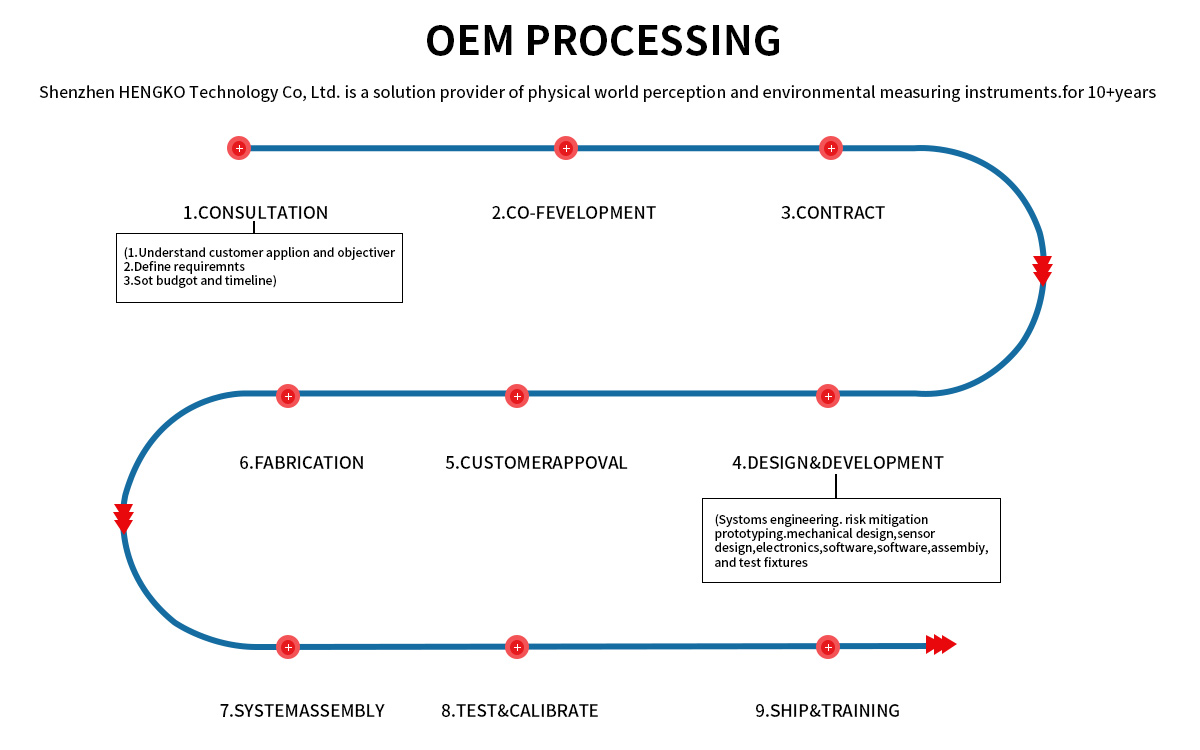

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!