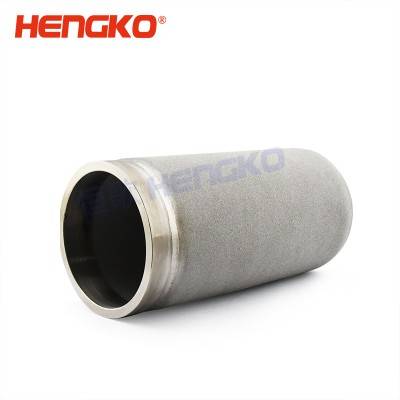

304, 316 316L micron filtration stainless steel wiremesh pleated sintered metal refillable filter cylinders

Well-run gear, qualified revenue workforce, and superior after-sales companies; We've been also a unified huge loved ones, anyone persist with the organization benefit "unification, determination, tolerance" for 304, 316 316L micron filtration stainless steel wiremesh pleated sintered metal refillable filter cylinders, Therefore, we can meet different inquiries from different consumers. You should find our web page to check additional info from our products.

Well-run gear, qualified revenue workforce, and superior after-sales companies; We've been also a unified huge loved ones, anyone persist with the organization benefit "unification, determination, tolerance" for China Filter Cylinders, Filter Cartridge, micron stainless steel filtration, sintered metal filter cylinder, Stainless Steel Filter, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

5 10 25 micorn porous 316L stainless steel powder/wire mesh sintered metal refillable filter cylinder

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh in high temperature. They have been widely used in environmental protection, petroleum, natural gas, chemical, environmental detection, instrumentation, pharmaceutical equipment and other fields.

HENGKO nano micron pore sized grade stainless steel filter tubes have excellent performances of smooth and flat internal and external tube wall, uniform pores and high strength. The dimensional tolerance of most models is controled within ±0.05 mm.

Want more information or wouldl like to receive a quote?

Click the Online Service at the top right to contact our salespeople.

E-mail:

ka@hengko.com sales@hengko.com f@hengko.com h@hengko.com

1. Accurate pore size, uniform and even-distributed apertures. Pore size range: 0.1um to 120 micron;

2. Good breathability, fast gas & liquid flow rate and uniform divergence. it is far superior to other peer products with the optimization of special process in HENGKO.

3. Good filtration dustproof and interception effect, high filtration efficiency. The pore size, speed of the flow and other performances can be customized as requested;

4. High supporting load capacity, no need to use other auxiliary supports, can be directly used as structural elements;

5. Stable structure, particles are tightly bound without migration, almost inseparable under harsh environment;

6. High fatigue strength and impact stress, high pressure resistant, suitable for applications with high pressure difference and flow rate. Sintered porous stainless steel filter elements for long-term usage under high pressure fluid (40mpa) conditions are available;

7. Resistance to high temperature and heat shock. HENGKO stainless steel filter elements can operate at 600 degrees celsius, can withstand high temperature even in oxidized atmospheres;

8. Excellent functions of separation and noise reduction as a result of special multidimensional honeycomb nested capillary structure;

9. Different from other peers, HENGKO stainless steel filter elements haven't been corroded in a variety of environments. The performances of anti-corrosion and rust-proof are close to dense stainless steel products;

10. More than 10K product sizes and types to choose from, customizable as needed for stainless steel filtering products with multiple complex structures;

11. Tiny diameter( 5-20 mm), the length for long filter tube can be up to 800 mm;

12. The processable dimension for plate filter can be up to L 800 * W 450 mm;

13. The maximum diameter for disc filter can be up to 450 mm;

14. Exquisite product appearance will upgrade your product level and image greatly as apparent parts;

15. A variety of cleaning methods are available, strong regeneration ability after reverse cleaning, long service life.

Q1. Why porous metal?

-- Filtration systems using sintered metal media for gaseous, solid and liquid separation have proven to be an effective and

efficient alternative to other separation methods that can be vulnerable to pressure peaks, high temperatures and/or corrosive

environments. Sintered metal is highly efficient in removing particulates, delivers a reliable performance, is easy to clean and has

a long life in comparison with leaf filters, filter bags and plate and frame filters.

Q2. What kind of structures can you make?

-- We make various types like disc, tube, cup, cartridge, plate, etc.

Q3. Do you provide customized services?

-- Yes, of course.

Q4. If samples available?

-- Sure, no problem.